Founded in 1989

Shuanglong Group has always upheld the mission of "Moving Forward with Strength." Since its establishment in 1989, the company has been deeply rooted in China's high-end equipment manufacturing sector. With a comprehensive industrial chain covering various mixing equipment, industrial motors, and valve castings, Shuanglong Group has become a benchmark national high-tech enterprise integrating R&D, design, manufacturing, and services.

Industry Solutions & Applications

In response to China's new energy initiatives, advanced manufacturing strategies, carbon neutrality goals, and energy efficiency upgrade policies, our products have reached every province across China and have been successfully exported to Asia, Europe, Africa, and Oceania, earning widespread international recognition.

Petroleum Industry

Petroleum operations require reliable motors to drive drilling rigs, compressors, fans, and pumps. Our explosion-proof motors and standard motors have been proven to deliver exceptional performance in harsh and hazardous environments, ensuring safety and reliability.

Coal Mining

From coal mining machines to ventilation systems, our motors power essential underground equipment. Designed specifically for explosive environments, these motors prioritize safety and reliability under the most hazardous conditions in coal mining operations.

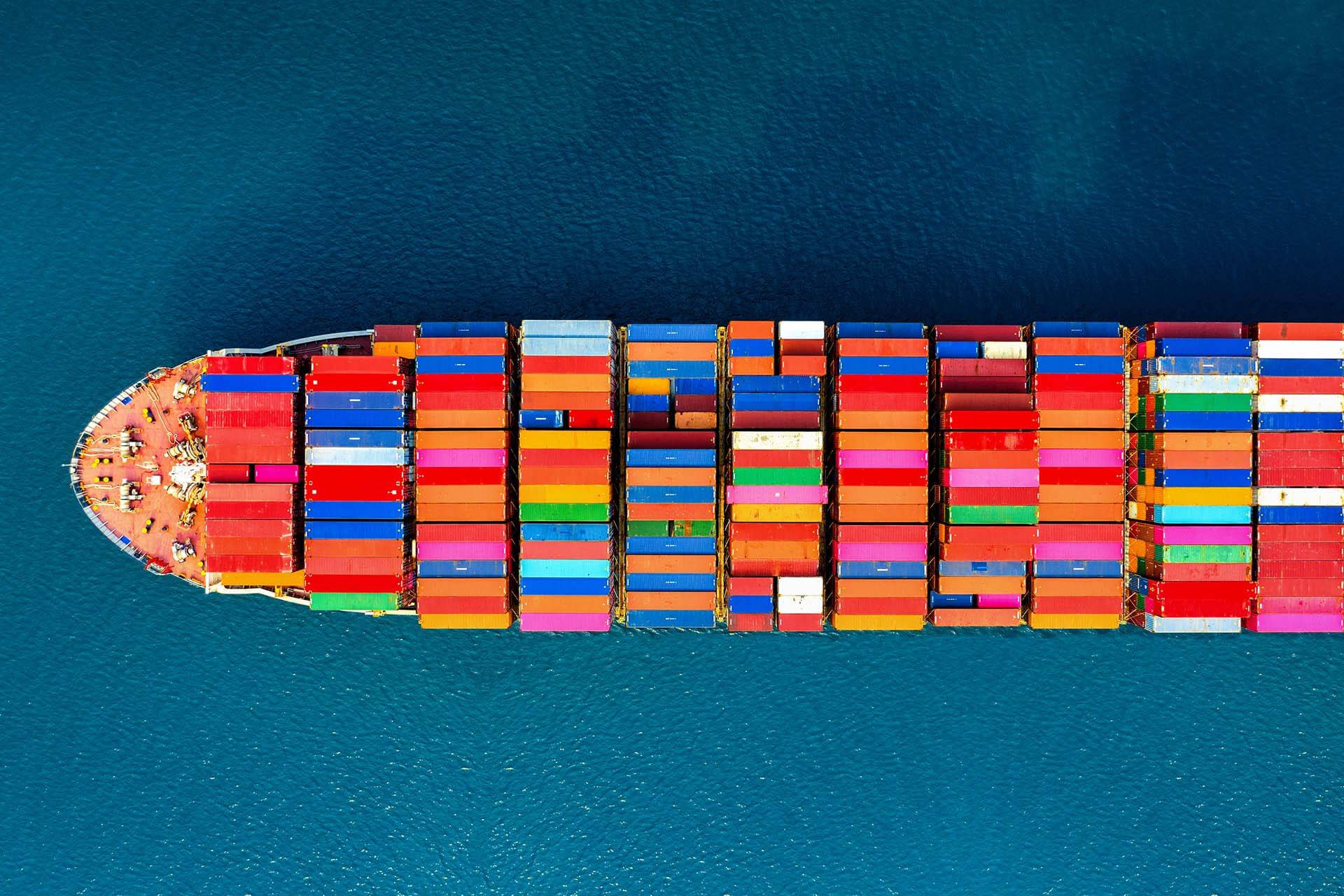

Marine & Shipping

Our marine-grade motors power propulsion, pumping, and deck machinery, offering corrosion resistance and reliable performance in demanding marine environments.

Electrical Equipment

Our motors power switchgear, transformers, and substation equipment, delivering reliable and precise performance for stable power transmission and distribution networks.

Transportation

Rail transit, metro systems, and electric vehicles rely on high-performance motors for traction, ventilation, and auxiliary equipment. Our motors deliver reliable operation under demanding conditions, ensuring passenger safety and energy efficiency for urban transit and high-speed rail networks.

Construction & Building

Construction sites and commercial buildings require motors to drive elevators, HVAC systems, water pumps, and material handling equipment. Our energy-efficient motors reduce operational costs while meeting strict building codes and safety standards, ensuring long-term reliable performance.

Chemical Industry

Chemical production demands motors capable of withstanding corrosive environments, extreme temperatures, and hazardous atmospheres. Our specialized motors for pumps, agitators, and reactor equipment are explosion-proof certified, ensuring safe and continuous operation in critical applications.

Metallurgical Industry

Steel mills and metal processing plants require heavy-duty motors to drive rolling mills, furnaces, cranes, and conveyors. Our robust motors deliver high torque and durability under harsh conditions involving dust, high temperatures, and heavy loads, ensuring maximum productivity and minimal downtime.

Our Products

No flashy rhetoric here—only the ultimate craftsmanship forged through countless refinements. With skilled hands, we calibrate the precision of Chinese manufacturing and carry forward the flame of craftsmanship rooted in Chinese civilization.

With a comprehensive industrial chain covering various mixing equipment, industrial motors, and valve castings, we have become a benchmark national high-tech enterprise integrating R&D, design, manufacturing, and services.

Let's Start a Conversation

With three production bases, an annual capacity of 7 million kW, and services reaching over 20 countries and regions worldwide, Shuanglong Motors is backed by professional expertise to provide you with full-process services—from product selection consultation and customized solutions to delivery and after-sales support. Feel free to contact us anytime to start our partnership.

Trusted by Customers and Businesses Worldwide

Frequently Asked Questions

What is the difference between explosion-proof motors and standard motors?

Explosion-proof motors are certified for use in hazardous environments where flammable gases or dust are present. They feature specialized sealed designs that effectively prevent internal sparks from igniting external combustible substances. Standard motors are suitable for general industrial use and do not have explosion-proof capabilities.

How do I choose the right motor size?

Motor size selection depends on several factors, including load requirements, operating speed, duty cycle, environmental conditions, and starting torque demands. Our technical team can help you calculate the optimal motor specifications based on your equipment parameters, ensuring efficient operation and long service life. Contact us with your application details, and we will provide customized recommendations.

What maintenance is required for industrial motors?

Regular maintenance includes visual inspections, bearing lubrication, vibration monitoring, thermal imaging checks, and electrical testing. Maintenance frequency depends on operating conditions and motor type. We recommend establishing a preventive maintenance schedule based on manufacturer guidelines. Our service team can provide detailed maintenance plans and support for your specific motor models.

Which certifications are important?

For general-purpose products, ISO 9001 certification and energy efficiency ratings (IE3 to IE5) are essential. Hazardous locations require ATEX/IECEx certification, while marine applications need classification society approvals (CCS, DNV). Ensure that certifications meet your regulatory requirements.

How do high-efficiency motors save costs?

IE4/IE5 motors can reduce energy consumption by 15-30%, with a typical payback period of 1-3 years. Additionally, they operate at lower temperatures, which reduces cooling costs, extends service life, and lowers long-term maintenance expenses.